We provide solutions for all types of Boilers (Marine, Oil & Gas, Industrial and Power Plants). We Design & Supply steam boilers, hot water generators, thermic fluid heaters, waste heat recovery systems, process-integrated boilers, and boiler auxiliaries & accessories, offering reliable, highperformance systems across industries.

With expertise in handling a wide range of fuels (MDO, HDO, Coal NG Pulverized Coal) including biomass, industrial wastes, biofuels, and fossil fuels, we ensure safe, efficient, and optimized operation. Our services include retrofit, upgradation, fuel conversion, spares, and O&M, supporting clients throughout the lifecycle of their equipment.

Our Insulation team provides expert repair and reinstallation services for boiler systems, starting with the removal of damaged insulation and thorough surface preparation, including cleaning and rust treatment. We apply high-performance thermal insulation to reduce heat loss and improve energy efficiency, followed by the renewal of protective cladding to ensure longlasting durability. Finally, we verify system performance through thermal imaging and efficiency tests, ensuring optimal operation. This process enhances boiler efficiency, extends system life, and reduces long-term operational costs.

Our Commissioning support includes burner testing, calibration, and operational tuning to ensure your boiler is ready for a smooth startup. We optimize system performance for safe, efficient operation from day one. All safety protocols are carefully followed to minimize risk. Our team ensures the boiler operates at peak efficiency and reliability. Trust us for a seamless, trouble-free commissioning process.

Our refractory services include supply, installation, and repair of high‑quality materials for marine boilers. Proper refractory maintenance ensures efficient heat retention, stabilizes combustion, and protects critical components, reducing fuel consumption and minimizing wear in the most demanding marine environments.

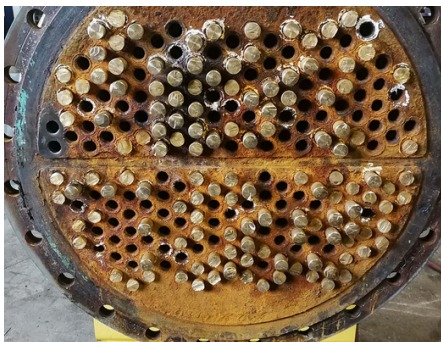

We restore your boiler’s thermal efficiency by removing scale, corrosion, and fouling from the water‑side. Our chemical cleaning and descaling solutions improve heat transfer, reduce fuel consumption, and enhance boiler reliability by ensuring clean, uniform waterlines, minimizing thermal stresses and potential failures.

Based on recommendations precision surface preparation, hightemp protective painting, and advanced insulation reinstallation. We restore thermal efficiency, eliminate corrosion risks, and extend boiler life with robust, shipready solutions

We ensure continuous, efficient operation of your marine boiler systems with thorough inspections, preventive maintenance, and troubleshooting, all in compliance with Class and regulatory standards. Our certified engineers provide real-time diagnostics and tailored solutions to avoid downtime and enhance boiler performance, keeping your vessel running smoothly.

We offer expert repairs, full system design upgrades, and retrofitting for all types of marine boilers. Whether replacing pressure parts, burners, or modernizing control systems, our solutions increase efficiency, reduce emissions, and extend the lifespan of your equipment while adhering to the highest safety and regulatory standards.

We optimize burner performance with advanced automation solutions, including tuning, system upgrades, and safety interlock configurations. Our expertise in burner management systems (BMS) and ignition controls ensures efficient fuel use, reduces emissions, and enhances combustion stability, improving overall boiler reliability and safety.

We provide comprehensive electrical and instrumentation support for marine boilers, including calibration, troubleshooting, and system upgrades. Our services enhance accuracy and reliability in temperature, pressure, and flow measurements, ensuring your boiler’s electrical systems are safe, stable, and compliant with marine standards.

We optimize boiler performance through detailed analysis of combustion efficiency, heat transfer, and system control. Our study identifies improvement areas such as fuel-air ratios, steam stability, and thermal losses, providing a roadmap for enhanced fuel economy, increased efficiency, and reduced emissions.

We deliver precise, inspections using UT, RT, MPI, DPI, In-situ Metallography/Replica and borescope technology to detect internal faults such as corrosion, cracking, and tube degradation. Our diagnostic services extend boiler lifespan, prevent failures, and ensure optimal operation by providing clear, actionable insights without dismantling equipment.

Our API engineers and designers perform integrity evaluations of boiler pressure parts as per API 579-1 and ASME-FFS standards. Using advanced analysis, we assess corrosion, metal loss, and stress levels to determine serviceability, recommend repairs or replacements, and provide re-rating guidance. Through RLA and life-extension studies, supported by material testing and corrosion assessment, we estimate remaining life, plan cost-effective replacements, reduce risks, and extend equipment service life—all while ensuring compliance with marine standards.

We perform detailed tube assessments to identify thinning, cracking, or other defects. Our services include controlled tube plugging or full tube renewal, restoring system integrity and minimizing downtime. This ensures that your boiler operates at peak efficiency, with increased reliability and reduced risk of tube failures.