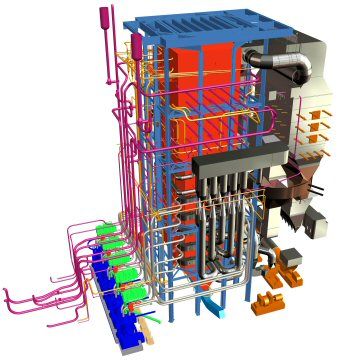

Mercury Energy Solution is a young and dynamic company offering a comprehensive range of industrial boiler systems, heat-transfer equipment, and energy solutions for diverse industries. We Design, Engineer & Supply AFBC & CFBC boilers, oil & gas fired systems, solid-fuel boilers, HRSGs, WHRBs, thermic fluid heaters, hot water generators, and heat exchangers, along with complete auxiliaries and spare parts.

Our solutions support power plants, process industries, manufacturing units, petrochemical facilities, food processing plants, and large commercial establishments. Backed by a strong network of trusted manufacturers and technology partners, we deliver high-quality equipment and services at competitive prices.

We provide comprehensive design and engineering solutions for industrial boiler and energy systems. Our services include system design, equipment selection, detailed engineering, and integration of mechanical, electrical, and control systems. All designs are developed to meet applicable international standards, site conditions, and client-specific operational requirements, ensuring safety, reliability, and long-term performance.

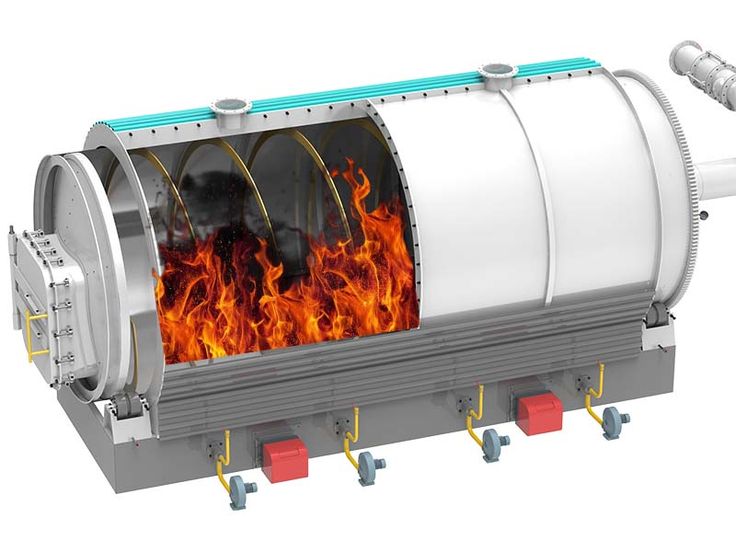

We specialize in fuel conversion projects and firing system upgrades to enable boilers and thermal plants to operate on alternative fuels such as biomass, bagasse, and mixed fuels. Our retrofit solutions improve combustion efficiency, reduce emissions, and extend the operational life of existing equipment while minimizing downtime during execution.

Our upgrade and conversion services enhance the capacity, efficiency, and environmental performance of existing boiler systems. We undertake combustion system upgrades, control system modernization, and mechanical modifications to align older installations with current operational and regulatory standards.

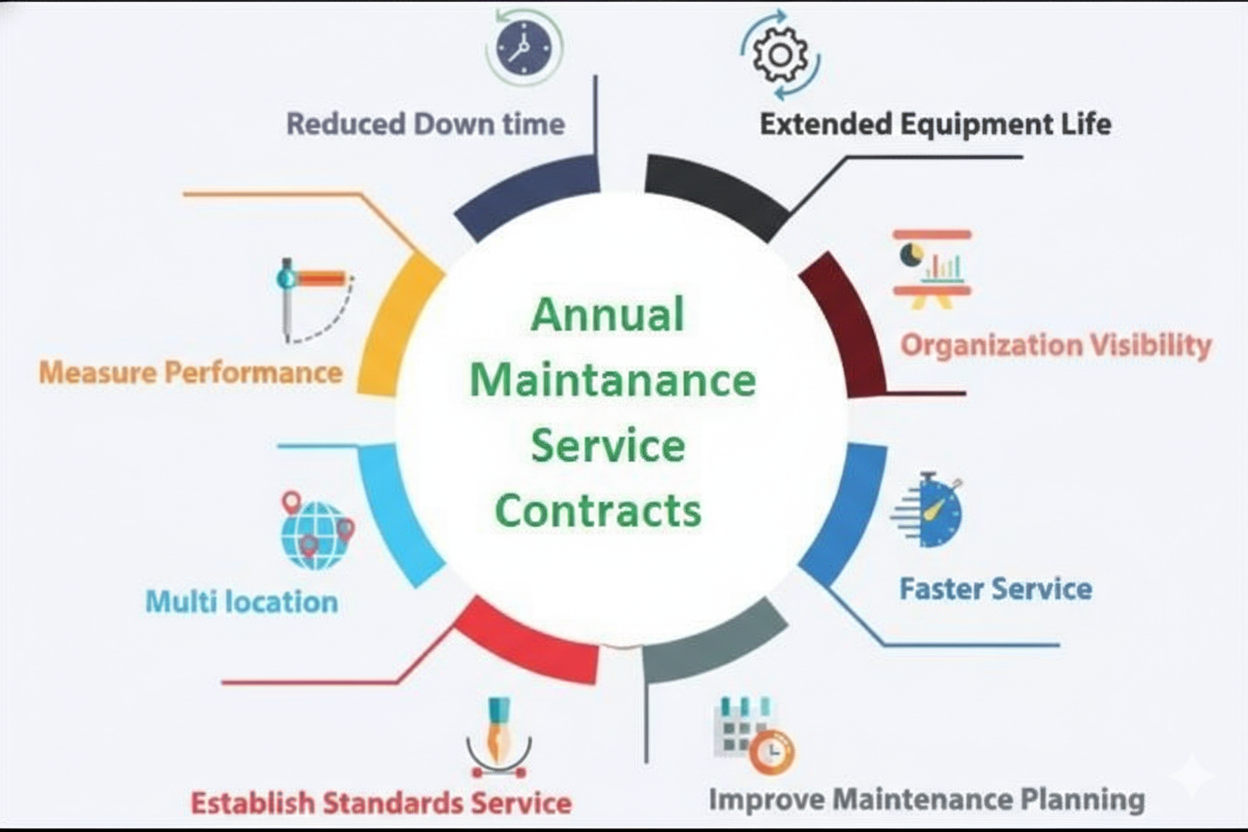

We offer structured Annual Maintenance Contracts (AMC) for boilers and auxiliary systems, covering preventive maintenance, breakdown support, inspection, and performance monitoring. Our AMC programs are designed to ensure maximum plant availability, reduced operational risk, and predictable maintenance costs throughout the year.

We provide end-to-end project management services covering planning, engineering coordination, procurement support, site supervision, commissioning, and documentation. Our experienced project team ensures timely execution, quality control, and strict adherence to safety and regulatory requirements.

Our performance improvement studies involve detailed system audits, combustion analysis, heat balance evaluation, and operational reviews. Based on these assessments, we recommend practical modifications to enhance thermal efficiency, fuel utilization, and overall plant performance.

We support power plants in reducing CO₂ emissions through optimized combustion strategies, fuel blending, efficiency improvement measures, and retrofit solutions. Our approach focuses on lowering specific fuel consumption while maintaining stable operation and compliance with environmental norms.

We provide reliable sourcing and logistics solutions for biomass and bagasse fuels tailored to industrial boiler applications. Our supply chain management ensures consistent fuel quality, moisture control, and dependable delivery to support uninterrupted plant operations.

Our boiler retrofitting services include pressure part modifications, burner and firing system upgrades, economizer additions, and control system enhancements. These retrofits improve efficiency, capacity, and safety while extending the service life of existing boilers.